Developing robots that continue to take on new challenges for more than

40 years

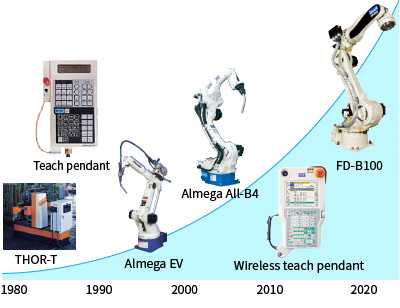

DAIHEN developed the first arc welding robot, the Soar series, in 1980. In 1991, we developed synchro motion, the world's first cooperative control system for multiple robots*1, and brought new scope to automation.

For 40 years, we have been close to our issues at the forefront of industrial robots and contributed to the progress of automation.

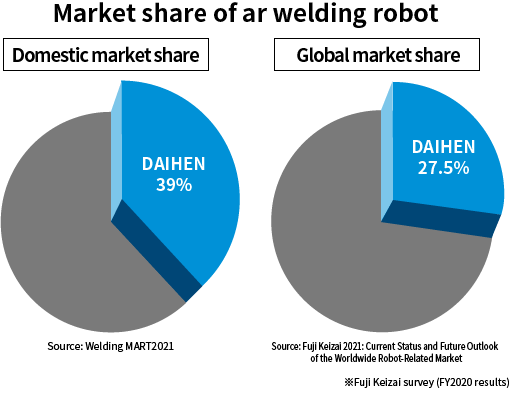

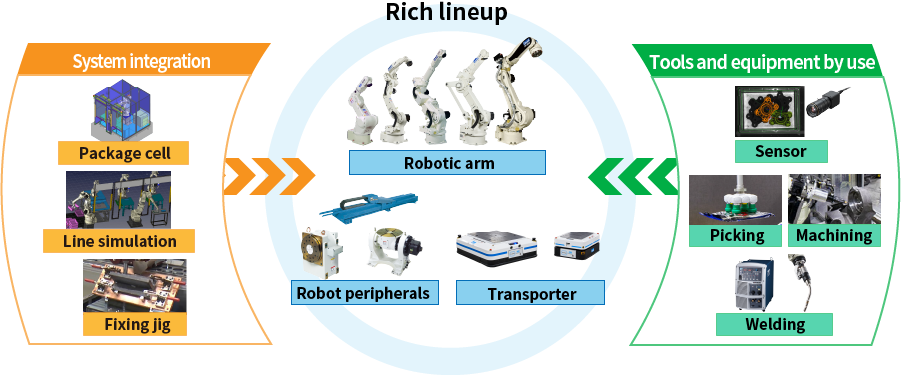

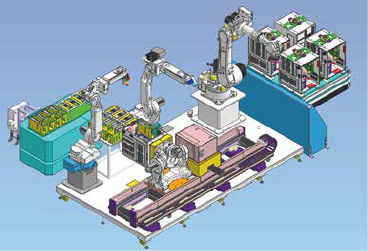

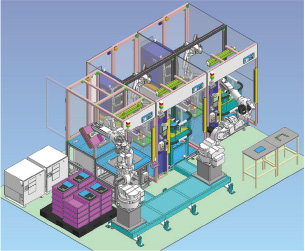

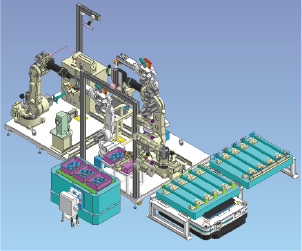

In addition to our global No.1 of arc-welding robots*2, we continue to develop products for a variety of applications, including bolting, fitting, transfer between processes, picking and sorting, inspection, painting, and polishing.

*1. Our survey

*2, Fuji Keizai survey (results for fiscal 2020)