Related products & functions

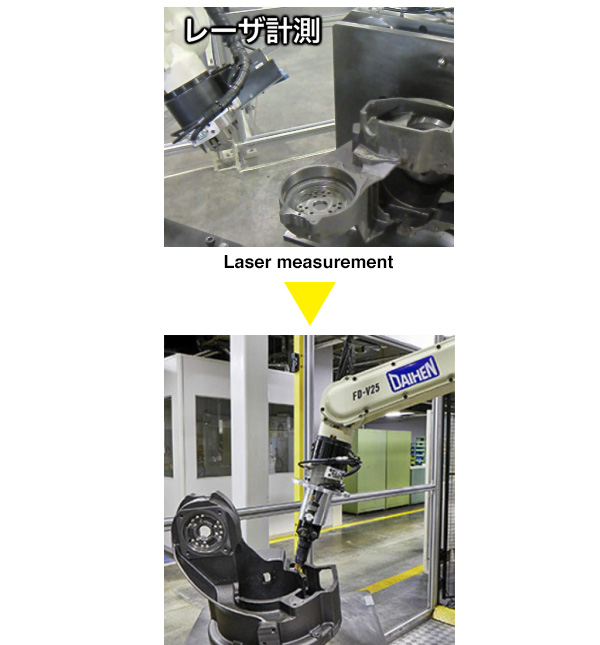

High-precision machining using laser sensors

Using our proprietary sensor technology, we have realized deburring work that requires precision with a simple configuration. Sensors using laser light can adapt to changes in surface conditions and materials.

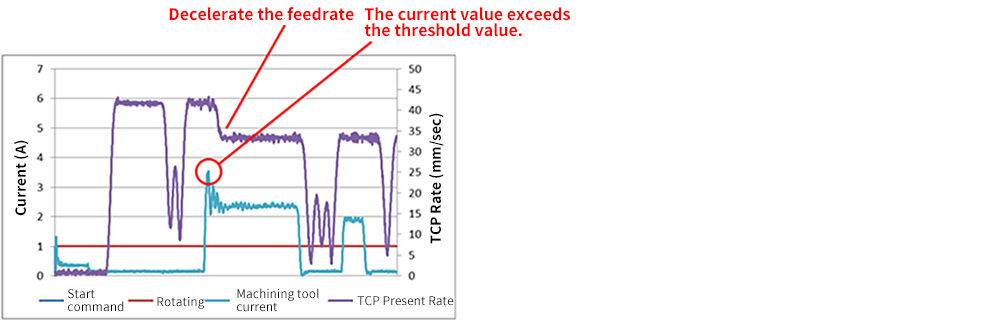

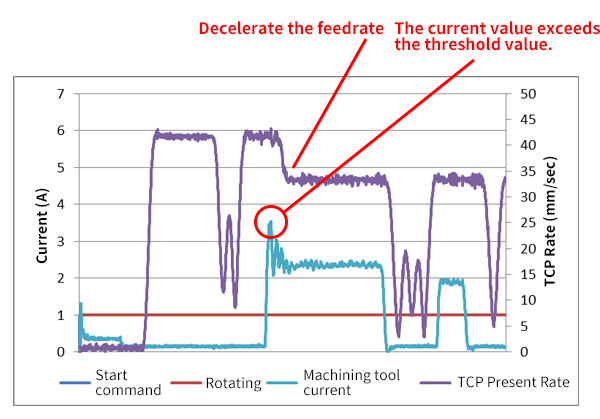

Improved cutting efficiency by monitoring cutting load

The cutting speed is automatically adjusted by monitoring the current of the tool motor. It contributes to longer tool life, and it is also possible to notify when to replace a tool.

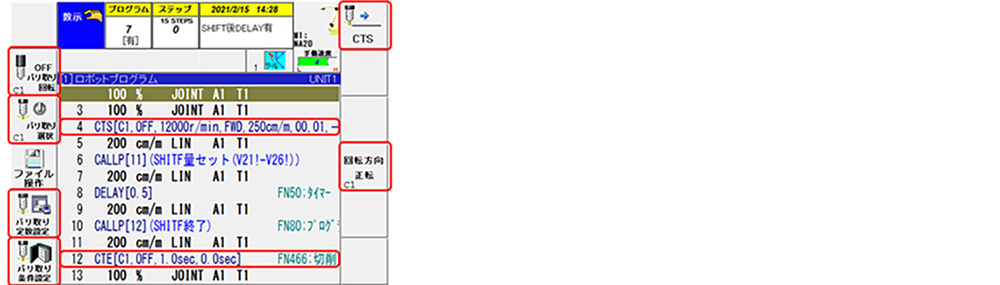

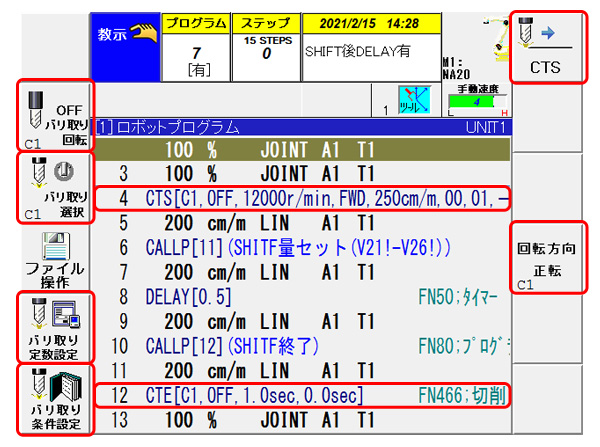

Easy condition setting by dedicated command for cutting and polishing

All cutting parameters can be set from TP. Dedicated instructions for cutting and polishing are provided as standard for easy teaching.