Main features

-

Simple manual operation realized

While teaching for a 7-axis robot tends to be a complex operation, Daihen's Synchro-motion technology has allowed for simple manual operation.

-

The world's first built-in welding power cable.

The welding power cable being built into the 7th axis robot is the first of its kind. Teaching can be done without concern of interference with jigs or workpieces.

-

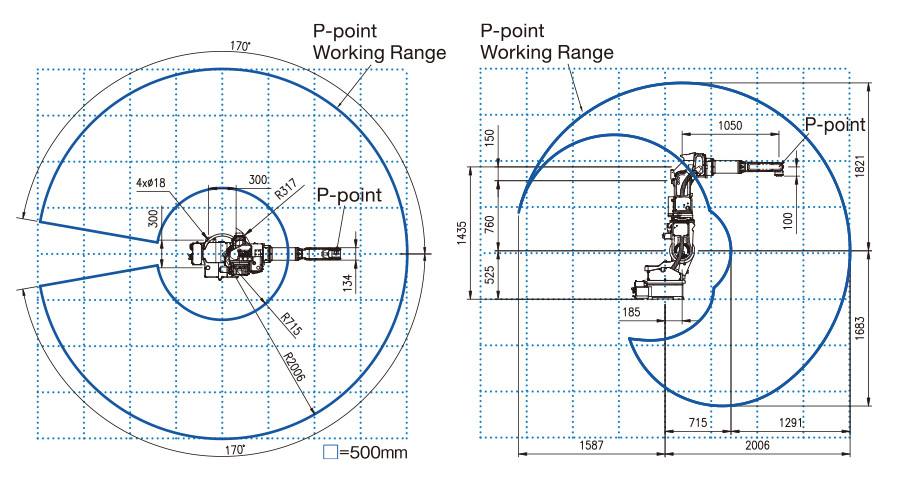

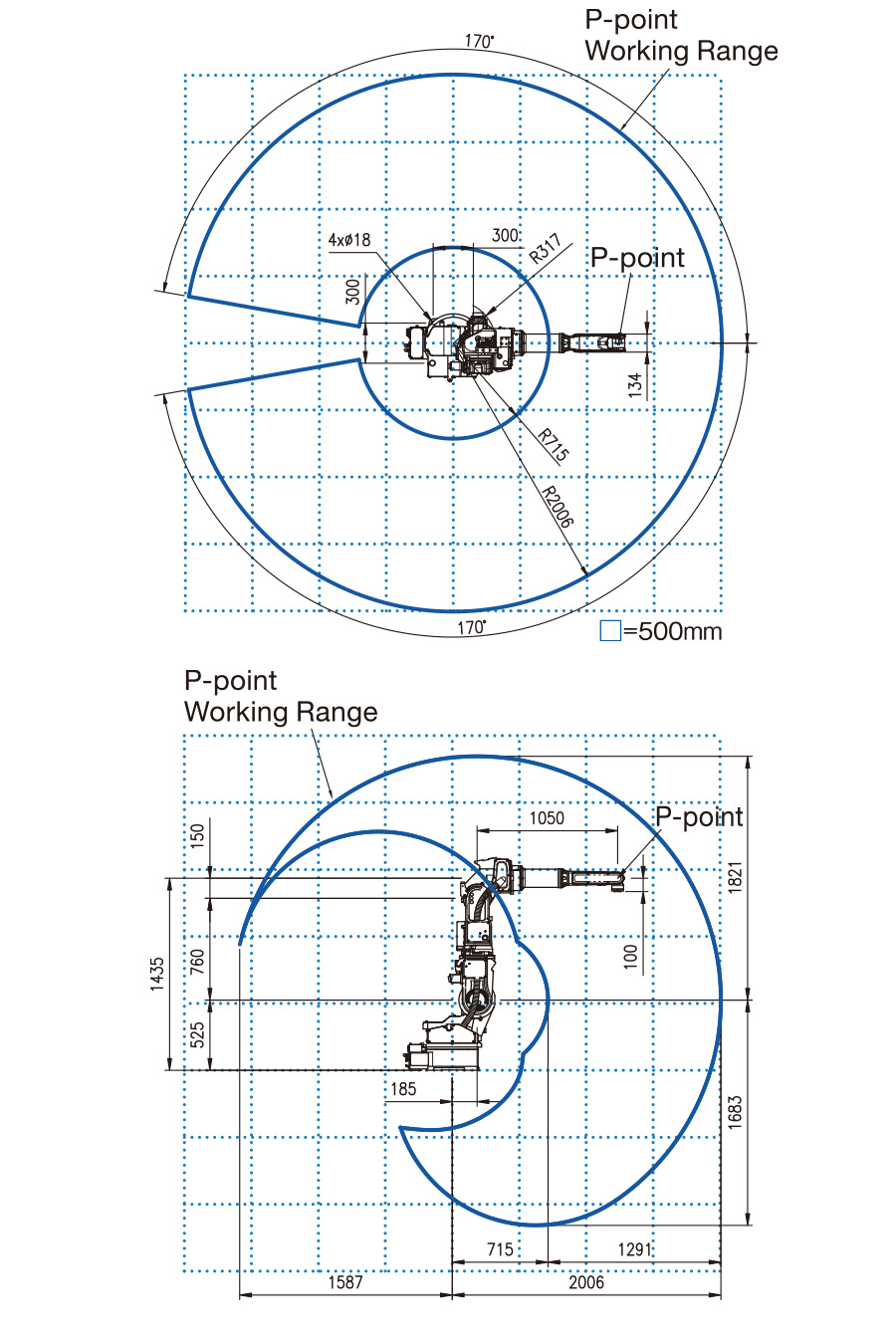

Applicable to a wide range of workpieces.

Applicable to everything from small parts to large workpieces because of extended reach.

Specifications

- Item

- Specifications

- Model name

- NVT8L

- Structure

- Vertical articulated type

- Number of Axes

- 7

- Wrist payload

- 8kg

- Weight

- 331kg

- Load of Upper Arm

- 20kg(*)

(Note) When loading the Max. payload capacity as the end effector.

These specifications are subject to change without prior notice.

Login

Login

Login

*User registration is necessary to download CAD data.

Be advised that the registration ID of anyone from another company in the same industry may be deleted without notice.

Explanation video

Automation utilizing existing equipment and spaceRobot system package for sheet metal processing

Transport between processes in 3 cells with the 7-axis robot

Pipe periphery welding with a cold tandem welding system