Product search

Search by specification

Search by Application

Search by category

Freeword Search

Case examples and video search

Search by industry

Search by Application

Search by category

Event

Freeword Search

Fully Automated Factory System Using AMR “AiTran” and Various Arms Automation of Transportation Within the Factory by Utilizing the Existing Layout and Equipment

Synchro-feed Evolution Most Suitable for EV Production Sites. High-quality Welding that Contributes to Zero Rework

Robot System for Screw Tightening One Robot Can Tighten Multiple Types of Screws in a Minimum Amount of Space

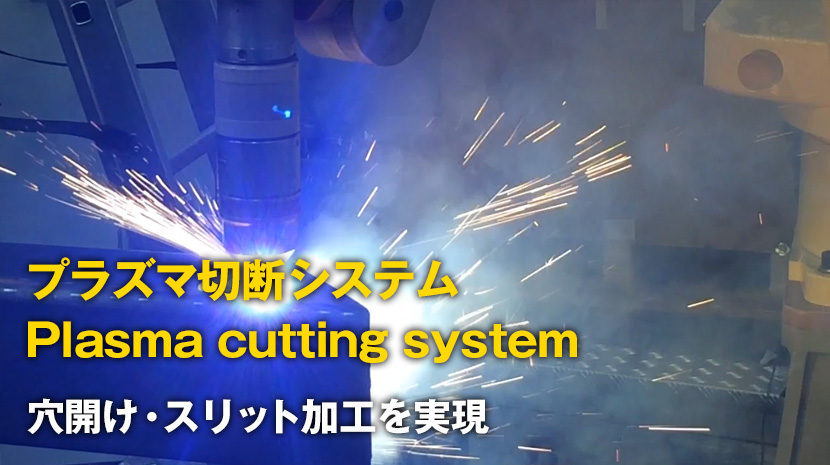

Robot System for Plasma Cutting High-quality 3D Cutting by Covering a Wide Area with One Robot

Teaching-Less System New Proposal for High-mix, Low-volume Production in Which Robots “See” and Generate Their Own Movements

Experience Direct Teaching Reduces Teaching with Intuitive Operation that Feels Like Welding by Hand

Arc Welding Optimal Cooperative Robot Package(Cart Type) Lean Automation Through Parallel Work Between Humans and Robots

Handling System Using Collaborative Robots Improve Productivity by Utilizing Existing Space and Equipment

Arc Welding Optimal Cooperative Robot High-quality Welding by Adapting to Various Welding Needs with a Full Range of Functions

Teaching-less system by tablet Three-step by 'taking, selecting, and sending'

High trajectory accuracy for precision TIG welding Arc Welding Optimal Collaborative Robot

Remote Maintenance Easy, quick, and accurate on-site support using smartphones and the Internet

Arc Welding Optimal Cooperative Robot Easy transportation and simple operation expand the robot's applicable situations

High quality and ultra-low spatter welding system Wide applicable materials and joint shapes contribute to lightweight

High accuracy compact laser robot package Ultra-compact laser system

Screw tightening and fitting process multiple robots system Automating various assembly tasks with high accuracy in a limited installation space.

Synchro-feed Evolution Most suitable for electric vehicles production sites! Advanced high quality welding robot system

Factory transportation with AMR AiTran Collaboration between AMRs and robots

Remote Maintenance Evolved online support that tells the real of what's happening on the ground

Robot system case examples Tailoring the best robot system for each customer

Robot system package for sheet metal processing Automation utilizing existing equipment and space

High-efficiency production robot system for similarly shaped workpieces Simple production method that reduces teaching time

Automatic teaching program generation system An innovative teaching method by taking a picture!

Easy-to-teach collaborative robot Making collaboration with robots more accessible and easier

Force-feedback guided robotic assembly. Our reduction gear is assembled incorporating a force sensor mount to our robot end-of-arm.

FD-V210

Screw-driving robot system An automated system that uses a robot for everything including: picking up bolts, applying screw lock materials, and screw fastening.

FD-V210

Plasma cutting system Square pipe cutting and slit and hole processing with a highly accurate robot and positioner.

FD-V20A,FD11,FD-A20

Sealant dispensing system Transformer casing lid adhesive dispensing application (0.3m/s)

AⅡ-V20(FD-V25)

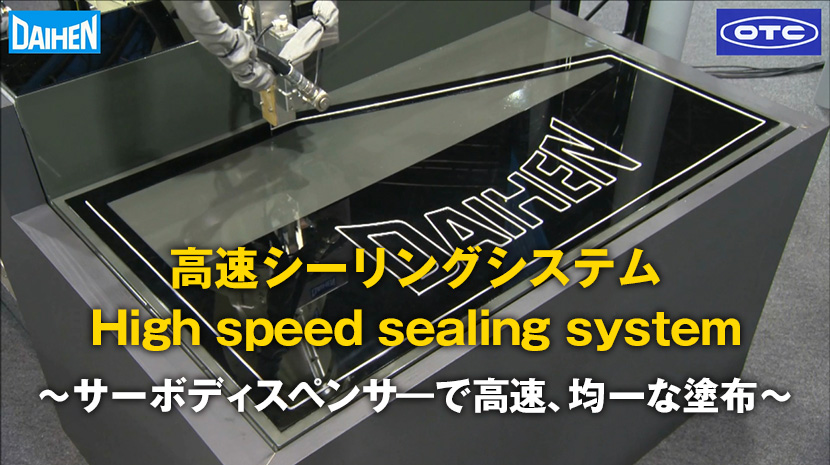

High-speed sealing system Stable sealing can be done even at the maximum 1.5m/sec. high speed operation.

FD-V20S

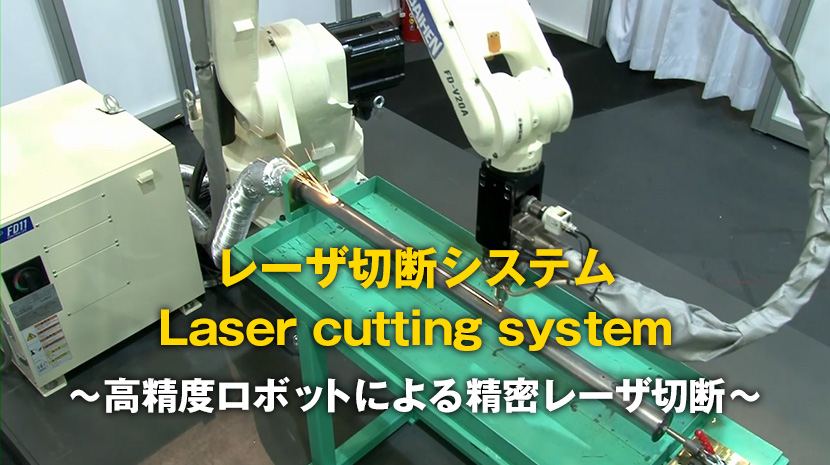

Laser cutting with a world class highly accurate robot High-Accuracy robot for small circle cutting, saddle shape 3 dimensional cutting and straight line cutting. World-class straight track and circular arc track accuracy across the entire work envelope.

FD-A20

Parts loading/unloading to the machine tool by 7-axis robot 7-axis robot goes around the front of machine tool and achieves parts loading/unloading by its incredible flexibility.It can be installed without blocking the front side of machine tool.

FD-B4S

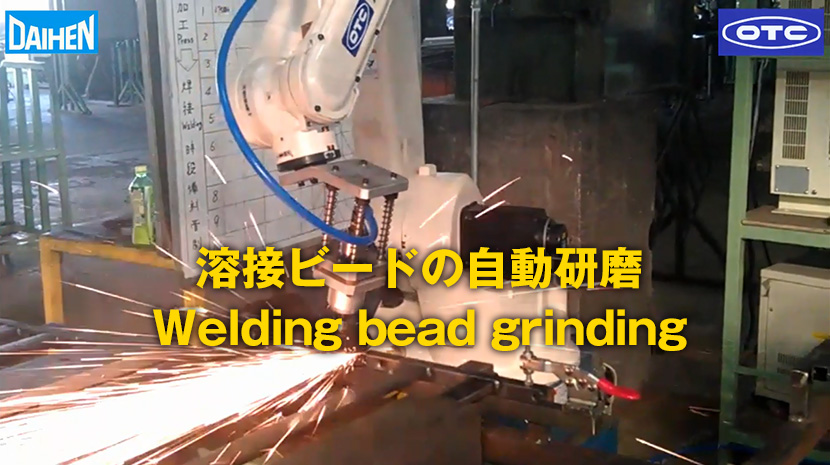

Automatic polishing of welding bead Polishing operation after welding process is automated.Robot has released operators from dust environment.

AⅡ-V20(FD-V25)

Parts loading/unloading to the forging machine Heated parts loading/unloading which requires speed is automated by robot.

AⅡ-V6 (FD-V8)

Parts loading/unloading to the pipe bending machine Achieving un-manned parts loading/unloading to the pipe bending machine.Productivity has been improved.

FD-V6(FD-V8)

Parts loading/unloading to the press machine Automated parts loading/unloading.Parts are loaded onto the pallet orderly by palletizing-function.

AⅡ-V50(FD-V50)

Conveyor robot between presses Achieving automation of simple work by 3 robots.Productivity and safety has been improved.

FD-V6L (FD-V8L)

Parts loading to the press machine Hard labor by 4 operators is automated by robot.Productivity and safety has been improved.

AX-V166 (FD-V166)

Transformer case material handling robot Material handling to and from the shot blasting equipment with a large handling robot.

FD-V210

Transformer casing automatic welding system Fully automated welding system with a large handling robot and an arc welding robot.

FD-V210、FD-V50、FD-B4(FD-B6)、FD-V6(FD-V8)

Screw-driving robot system An automated system that uses a robot for everything including: picking up bolts, applying screw lock materials, and screw fastening.

FD-V210

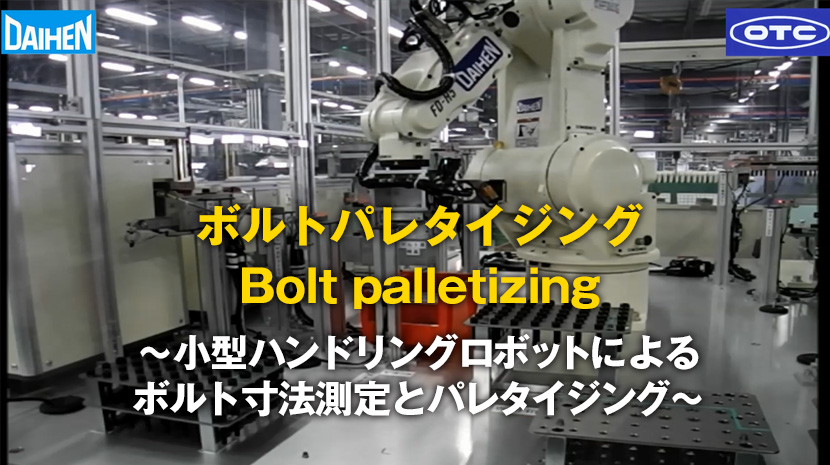

Bolt palletizing system Dimension calculation and palletizing while using the small handling robot.

FD-H5

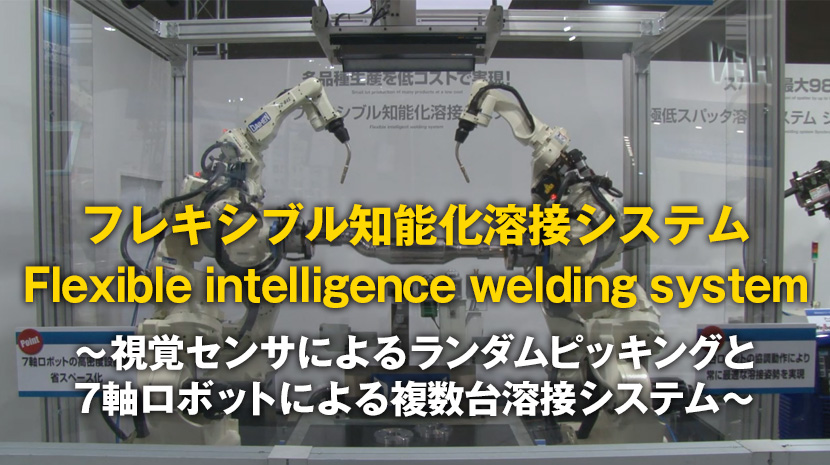

ulti-arm coordinated welding with our 7-axis robots. With the coordinated operation of the robot, dedicated jigs aren't needed for cutting costs, and setup times were greatly shortened.

FD-B4S,FD-V20S

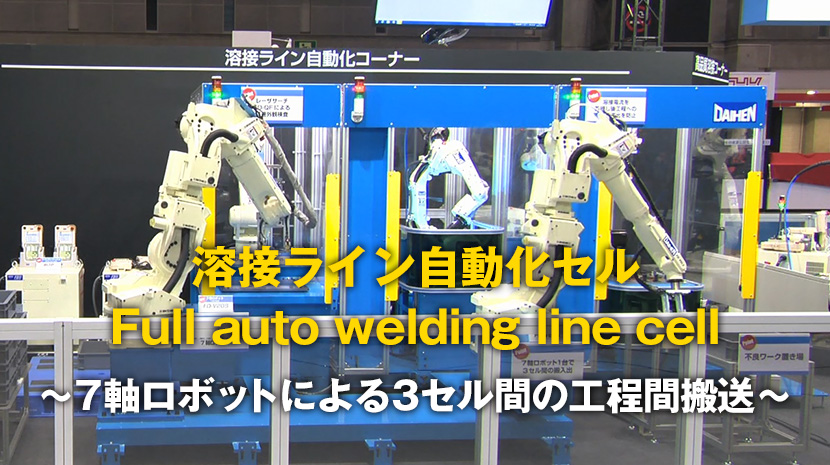

Transport between processes in 3 cells with the 7-axis robot The flexibility of the 7 axis robot, allows workpiece transport between 3 cells using 1 robot, reducing equipment costs.

FD-V6LS

7-axis robot performance video The flexibility of a 7-axis robot makes high density installations posibile with minimal space for equipment required.

FD-B4S,FD-B4LS,FD-V210

Synchro-feed welding system Ultra-low spatter welding resulting in 98% reduction of weld spatter.

FD-B6, WB-P500L,FD19,Synchro-feed welding system

Synchro-feed welding system3 Ultra-low spatter welding of soft steel (t12.0mm, fillet with weaving)

FD-B6,WB-P500L,FD19,Synchro-feed welding system

Synchro-feed welding system2 Ultra-low spatter welding of soft steel (t3.2mm, lap fillets).

FD-B6,WB-P500L,FD19,Synchro-feed welding system

Pipe periphery welding with a cold tandem welding system In ordinary MAG welding the molten pool is cooled by inserting a filler wire to minimize distortion via a low heat input.

FD-V6L,WB-P500L,FD11,Cold Tandem welding system,FD-V8L

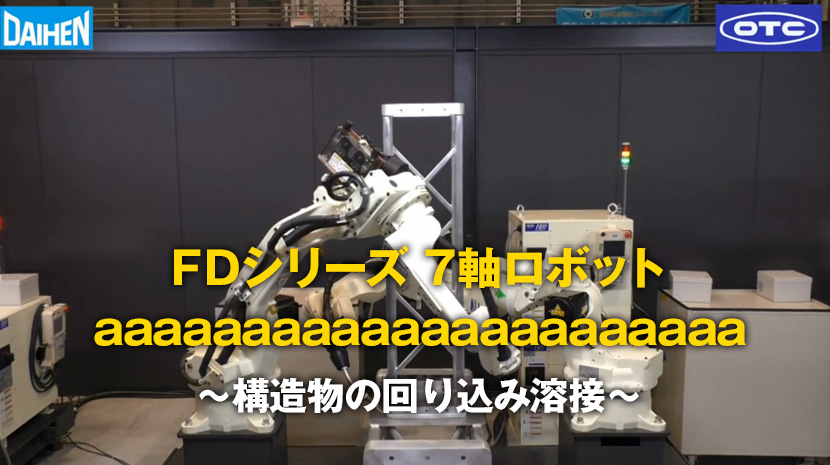

Full circumferential welding with a 7-axis robot. Flexibility of the 7-axis robot to deliver whole circumference welding without the need for additional positioners.

FD-B4,FD-B4S,FD11,FD-B6