Daihen Collaborative Robot Solves the Problem

of Introduction of Robots!

Collaborative Robot for

Arc Welding

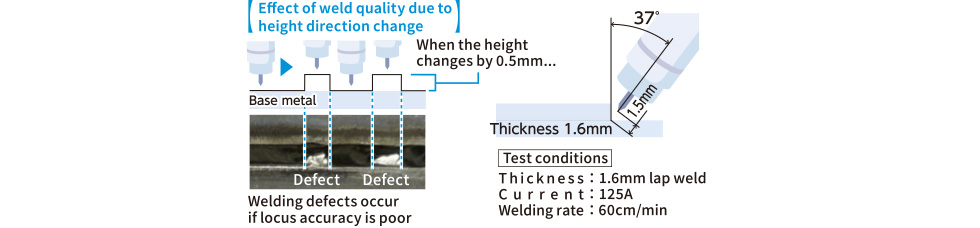

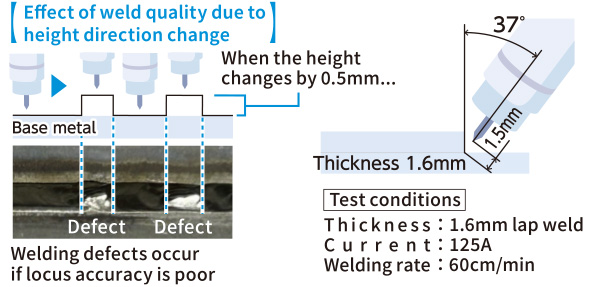

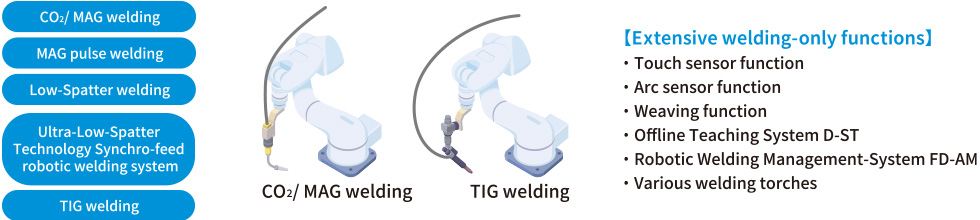

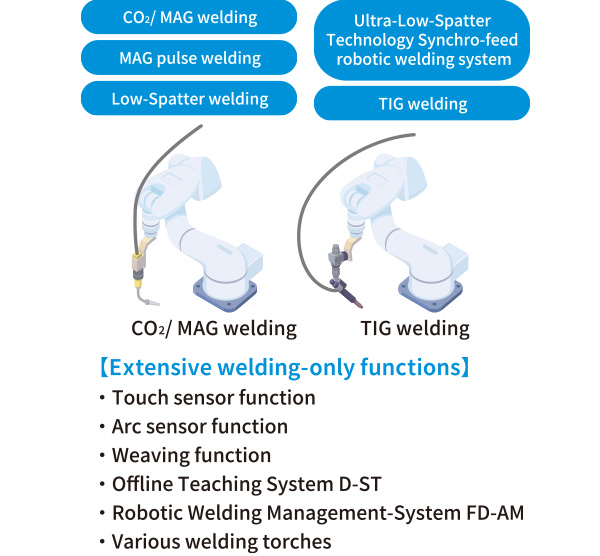

Daihen, who knows everything about welding, has developed a new control technology to improve the trajectory accuracy of linear and circular interpolation, which affects welding quality, and installed it in collaborative robots.

Achieves high-quality welding with stable trajectory accuracy equivalent to that of industrial robots.

Collaborative robots active in

Various sites

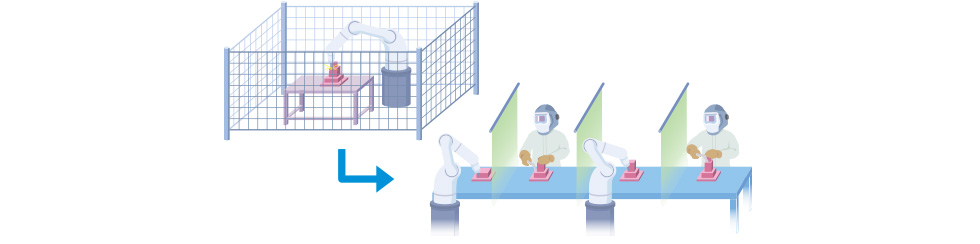

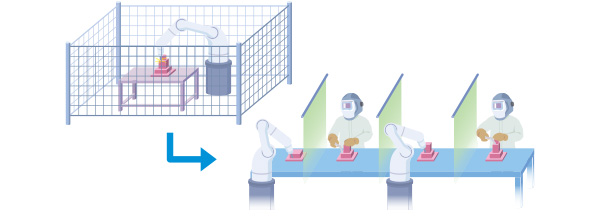

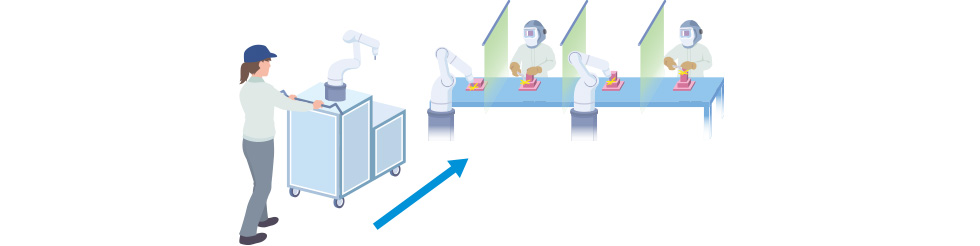

no separation from people by safety fence.

Therefore, it is no longer necessary to secure a large space for introduction like conventional industrial robots.

※1 If a safety fence is not installed, a risk assessment by the customer is required.

FD-VC4 complies with ISO 10218-1 safety standard for industrial robots.

In addition, the Robot Controller conforms to the international standard "ISO 13849-1PLd(Cat.3" and safety certification by a third-party certification body has acquired.

the robot stops.

In addition, it has an arm shape that prevents pinching of hands and fingers, and a design that eliminates corners, thereby alleviating impact during contact.

and run immediately.

Automation in large structures, such as shipbuilding, is also possible, and will be used in a variety of welding sites.

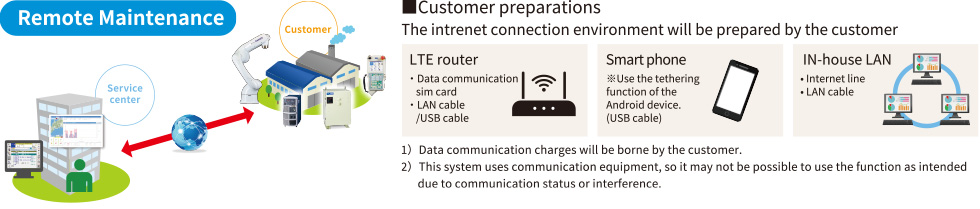

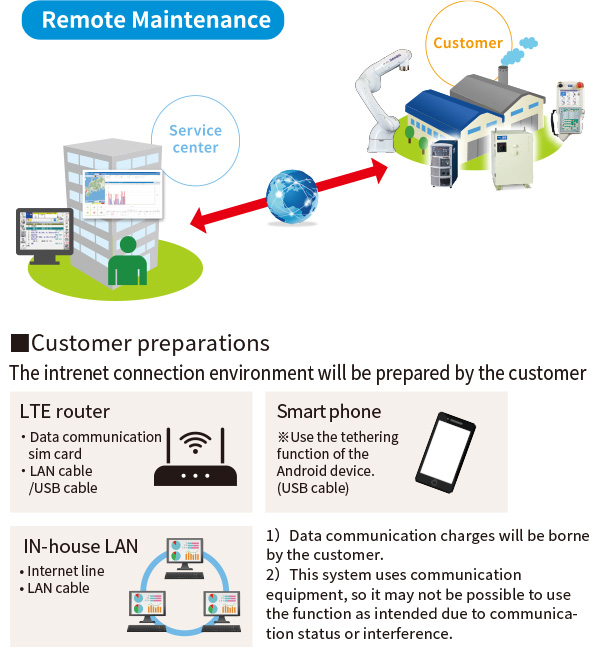

Safe and secure support can be provided as if a veteran service employee were present near the customer.

Specifications

- Item

- Specifications

- Model name

- NVC4

- NVC4L

- Structure

- Vertical articulated type

- Number of Axes

- 6

- Wrist payload

- 4kg

- Weight

- 37kg

- 47kg

(Note) These specifications are subject to change without prior notice.

*User registration is necessary to download CAD data.

Be advised that the registration ID of anyone from another company in the same industry may be deleted without notice.