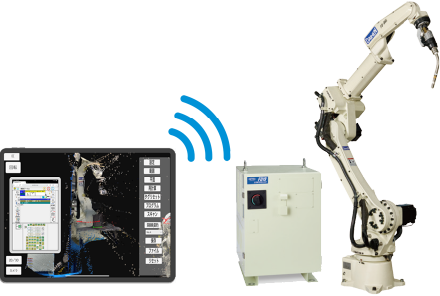

Teach-less system with tablet

Automatically generate robot programs by simply taking pictures and selecting tags. Solvethe challenges of robot teaching.

Automatically generate robot programs by simply taking pictures and selecting tags. Solvethe challenges of robot teaching.

Background and Challenges

One of the important issues when introducing robots is that they are unfamiliar with robot teaching and it takes time to operate.

For welding applications, there are issues such as not knowing the optimal welding posture and difficulty in adjusting the welding target position.

It takes time to get used to operating the robot, which slows down the production of the robot. DAIHEN's tablet-based teaching-less system solves this problem.

Challenges

when introducing robots

in the field

- Unfamiliar with teaching robots and taking time to operate.

- The optimum welding position is unknown.

- Difficulty in adjusting the aim position of welding.

Teach-less system with a tablet automatically generates a teaching program by simply shooting an object

DAIHEN's tablet-based teaching system is easy to teach by simply shooting AR marker and the target workpiece from iPad app without moving the robot / Selecting the weld point / Sending the program.

Therefore, it is also ideal for small-lot, large-variety workpieces.

Simple teaching by simply selecting and sending

Challenges

- Unfamiliar with teaching robots and taking time to operate

Function to solve challenges 1

Simple teaching with camera shooting without moving the robot

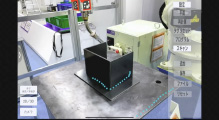

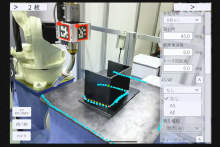

Take AR markers and objects from iPad app

Captures the workpiece at the same time as AR marker to acquire the relative position.

The robot recognizes the position of the workpiece, and candidates for the welding point are displayed.

Supports composite of multiple images

If the part you want to weld cannot be photographed at one time, you can take multiple shots and combine them to obtain welding line information.

Challenges

- The optimum welding position is unknown.

Function to solve challenges 2

Welding posture is set freely by numerical input.

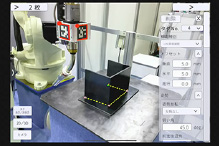

Touch the welding target position candidate.

When you take a picture, a candidate for the target position of the robot is displayed.

Select the welding start point, via point, and welding end point to be welded.

Challenges

- Difficulty in adjusting the aim position of welding

Function to solve challenges 3

Touch sensor automatically adjusts aiming position

High-precision position correction

with touch sensor function

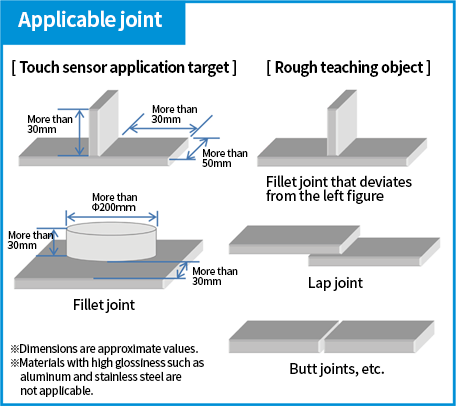

Fittings that meet the conditions can be position corrected by the touch sensor.

Teaching data created by iPad is automatically converted to high-precision position data required for arc-welding.

Touch sensor instructions are generated automatically, so there is no need to teach touch sensor instructions.

Transferring data from iPad

The weld line displayed on 3D and the weld position were checked, and the programme was sent.

The screen of the teach pendant can be displayed on the tablet, so it is also possible to check and edit the transferred programs.