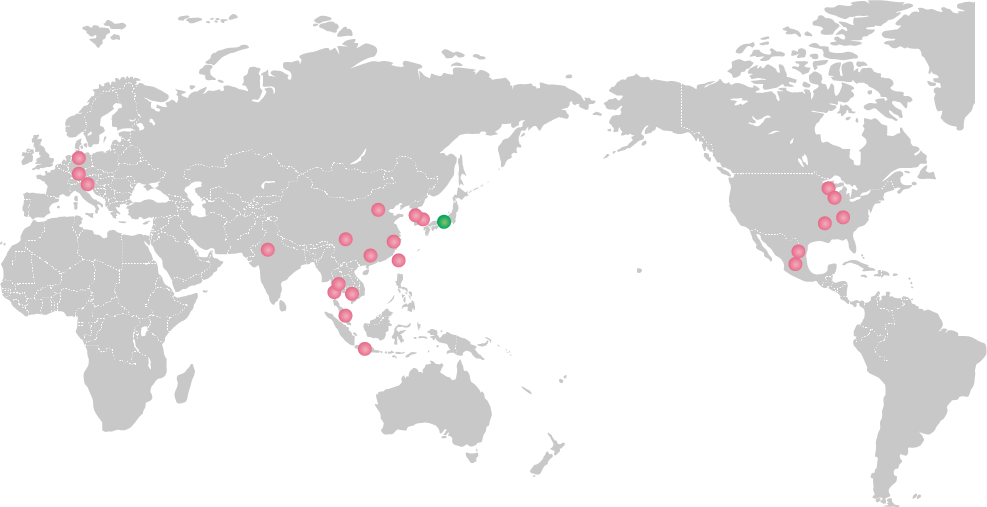

ExperienceRobot system demonstration showing the effect of introduction

Daihen's state-of-the-art technology and products and various robot packages that make use of their performance are exhibited.

・High-precision robots,

・Ultra-low spatter synchro-feed welding,

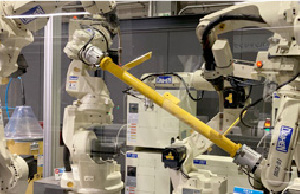

・Coordinated operation of multiple robots,

・7-axis robot that can be installed in high density,

・Accurate picking using visual camera sensor,

・In-process transportation package,

· Smart teaching etc..

You can check the effects and benefits after installation from a close distance.

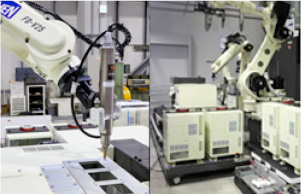

Handling and assembly package

- Assembly package that combines a visual sensor with an automatic screw fastening device

- Transfer package combined with various hands corresponding to various workpieces of different sizes and shapes

- Intelligent picking package that picks up workpieces on conveyors with visual sensors

- Inter-process transfer package that facilitates linkage with autonomous transfer carts by robots

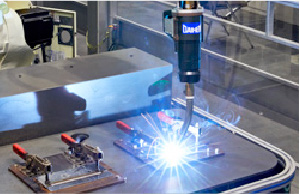

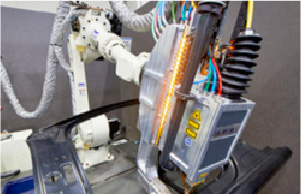

Laser processing package

- High-precision laser cutting package that combines a high precision robot with a laser oscillator and laser head

- Next-generation high-efficiency spot welding package using laser

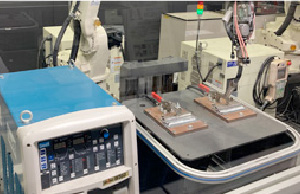

Arc welding package

- Joining various materials from thin plates to thick plates, stainless steel, aluminum, etc. using state-of-the-art technology Welding package

- Coordinated welding system that automates the pre-and post-welding processes by cooperative operation with multiple robots