Main features

- Traceability

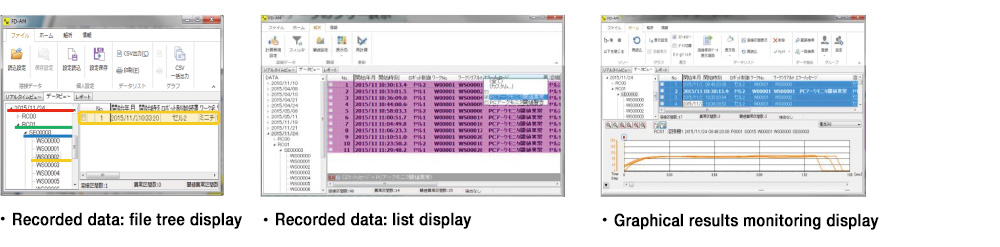

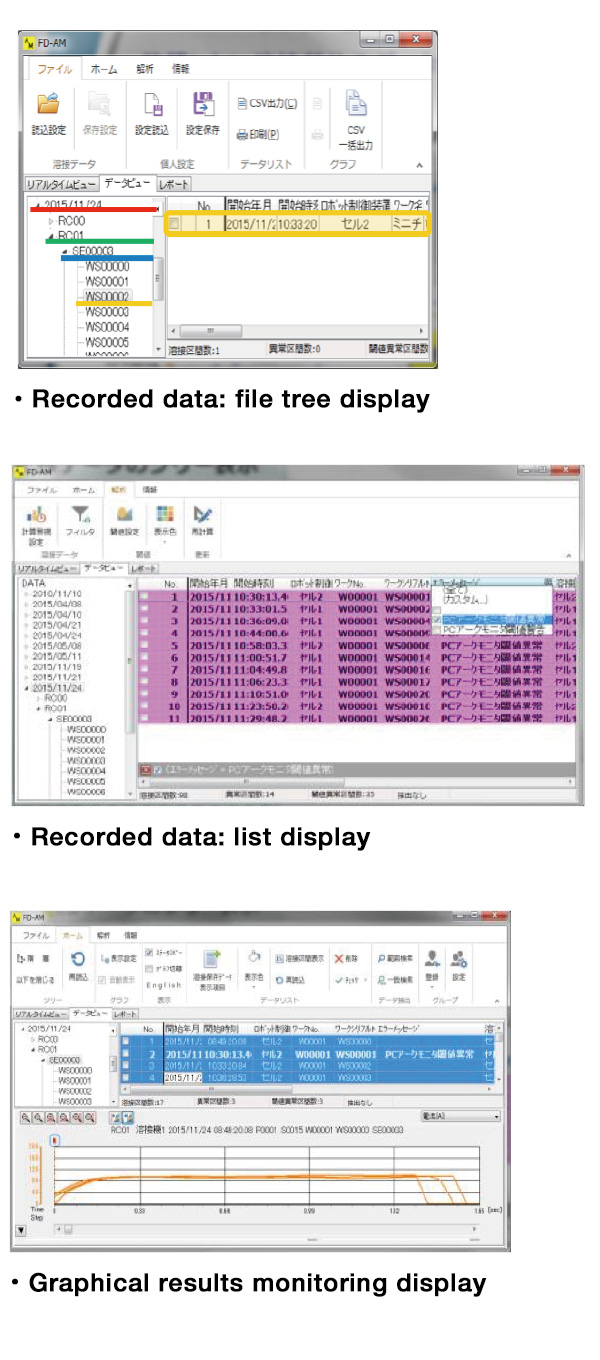

- Access to historical stored weld data for review.

Wireless LAN support, enabling reliable weld data recording in a remote office.

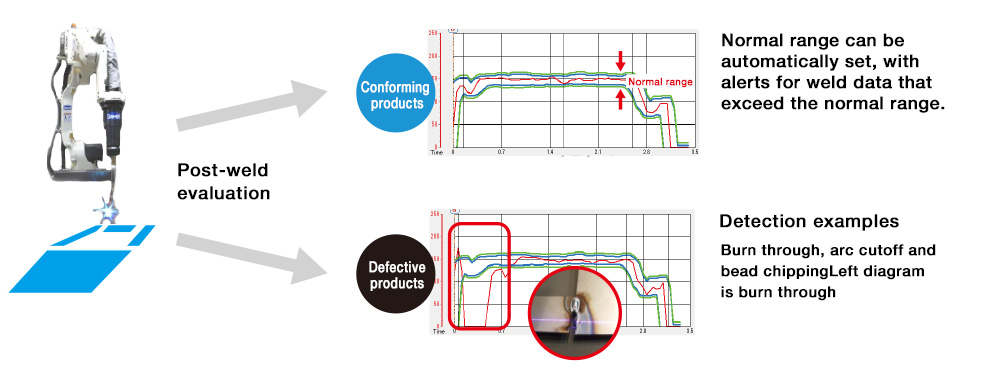

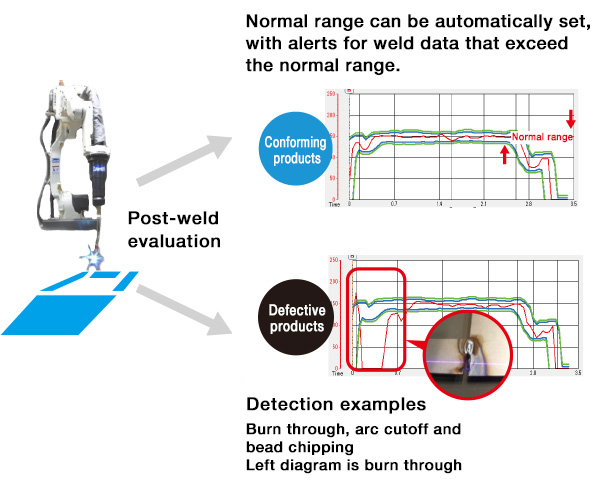

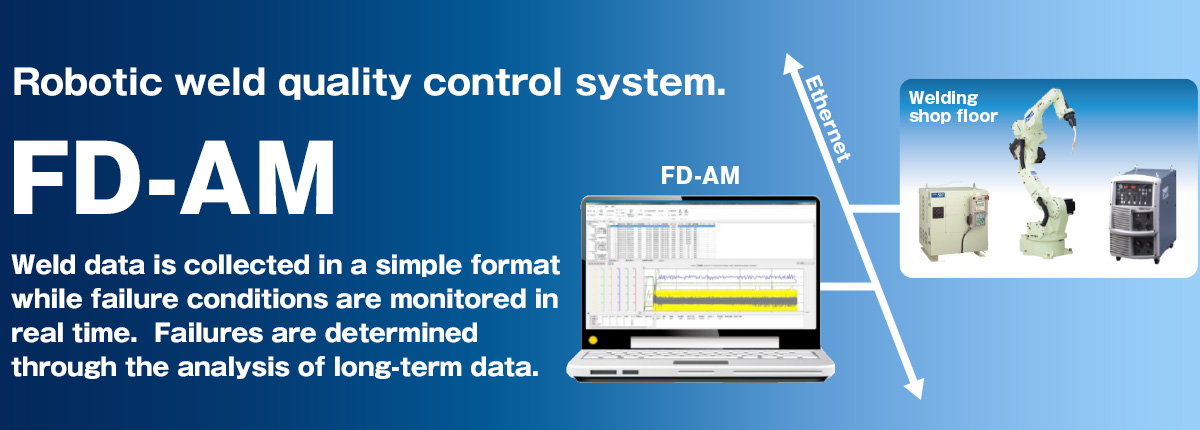

- Eliminate defective products before they reach your value-added, post-process operations.

- High-speed monitoring (10,000 times per sec) of all your welding data insures even the smallest failure won't be overlooked.

Reliable detection of weld data that deviates from the standard range insures that defective products do not reach your value-added, post-process operations.

- Weld failure detection

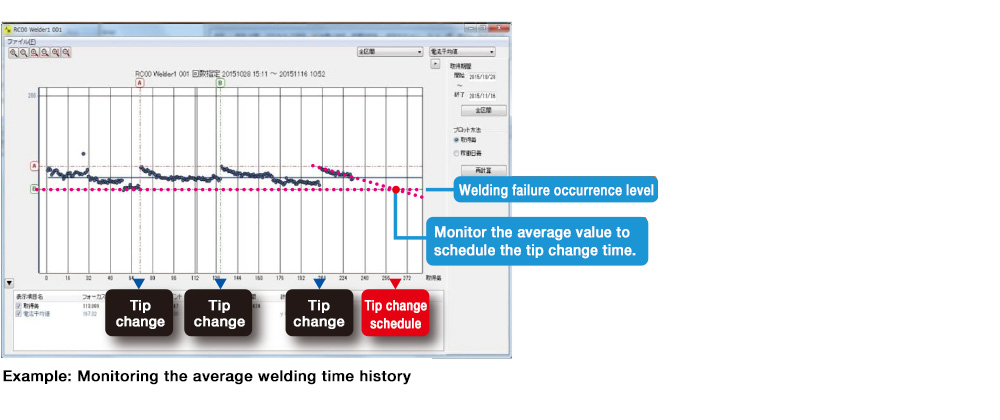

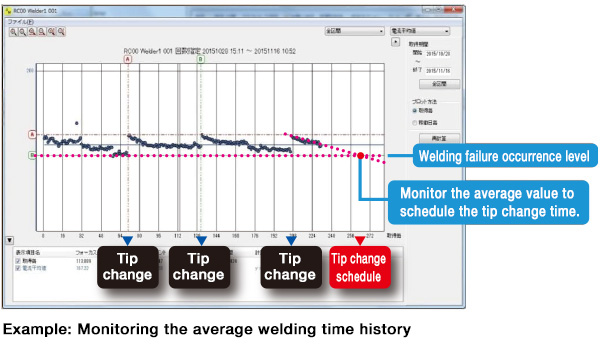

- Prevent weld failures through predicted condition changes and planned maintenance.

Through observation of a change in the Welding current, the tip can be changed before there's a welding failure.

Specifications

Basic structure

System requirements

| Product name | Specifications | |

|---|---|---|

| Basic software | Windows 2000、Windows XP Windows 7 | |

|---|---|---|

| (32bit Windows 8/8.1) (32bit) | ||

| Computer | Model | IBM PC/AT compatible computer |

| CPU | Intel Core i5 or greater (Intel Core i7 is recommended when the welding power is connected to more than 16 robots) |

|

| Memory | 4GB or greater (8GB is recommended when the welding power is connected to more than 16 robots) |

|

| Hard disk | 1GB or greater free space | |

| Disk drive | CD-ROM installed | |

| Network adaptor | Equipped with Ethernet port (RJ-45 socket) | |

| USB port | 1 or more (Needed for connection to the protection key) | |

- Basic software

- Windows 2000、Windows XP Windows 7

- (32bit Windows 8/8.1) (32bit)

- Computer

- Model

- IBM PC/AT compatible computer

- CPU

- Intel Core i5 or greater

(Intel Core i7 is recommended when the welding power is connected to more than 16 robots)

- Memory

- 4GB or greater

(8GB is recommended when the welding power is connected to more than 16 robots)

- Hard disk

- 1GB or greater free space

- Disk drive

- CD-ROM installed

- Network adaptor

- Equipped with Ethernet port (RJ-45 socket)

- USB port

- 1 or more (Needed for connection to the protection key)

Measurable items

- Welding current command

- Welding current

- Welding voltage command

- Welding voltage

- Welding speed command

- Welding speed

- EN ratio

- Spatter suppression ratio

- Wire feed speed command

- Wire feed speed (feeder)

- Wire feed speed (measurement unit)

- Wire feed load ratio

- Wire feed motor current

- Filler feed speed command

- Filler feed speed (measurement unit)

- Filler feed load ratio

- Gas flow rate command

- Gas flow rate

- Valve driving force

- First voltage

- Control board temperature

- Main circuit temperature

- Fan rotation No.