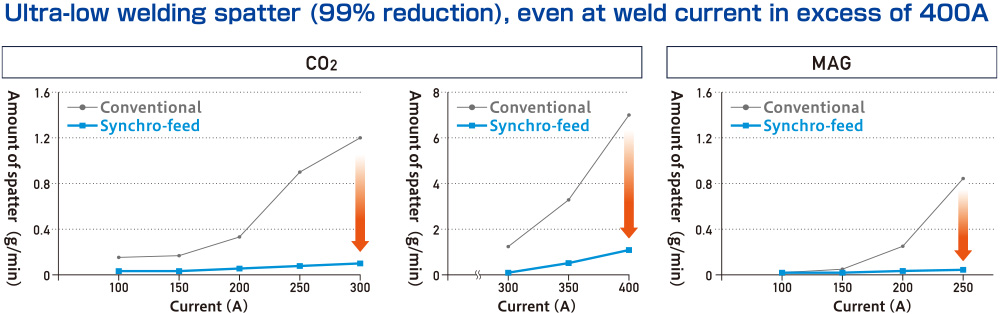

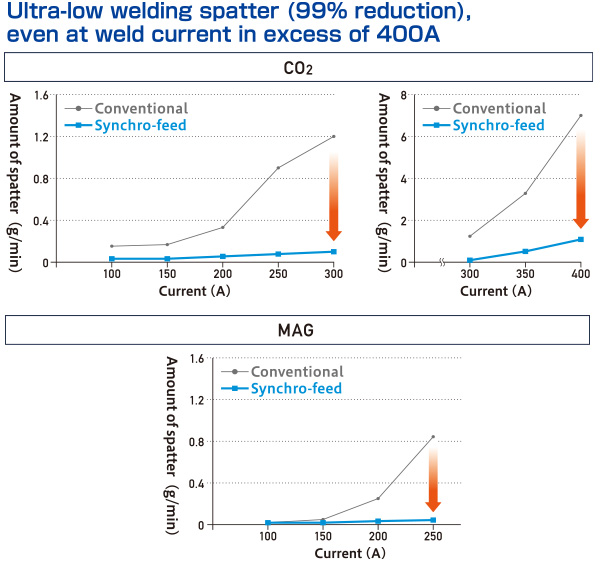

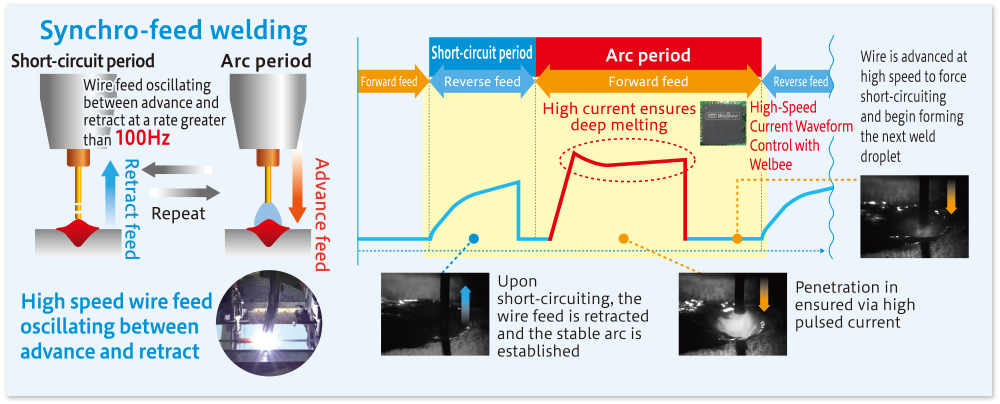

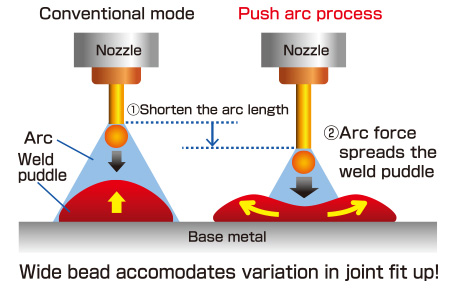

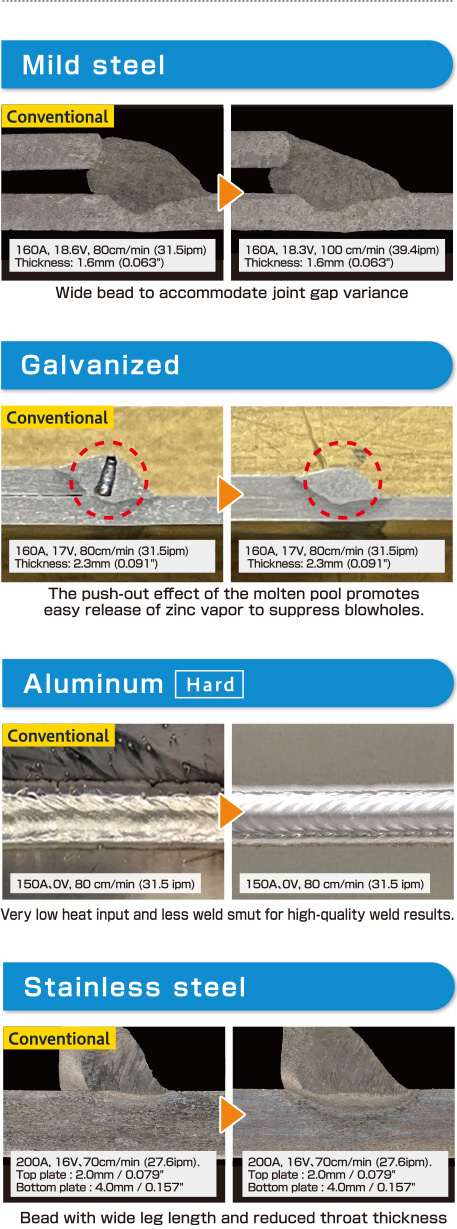

New evolutionary welding mode delivering ultra-low spatter,

high quality weld results Simple setup with

reduced maintenance requirements

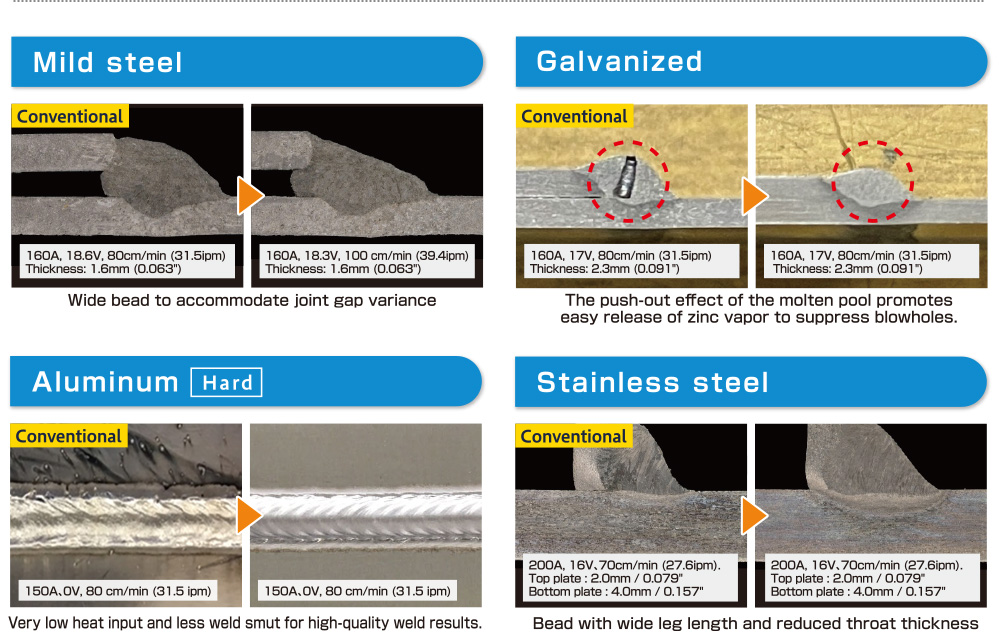

Compatible with various materials such as mild steel, stainless steel,

aluminum, New mode for even higher quality welding

Applications

(Aluminum)

(aluminum)

(galvanized steel sheets)

(high-tensile steel)

(Aluminum)

(Iron)

(stainless steel)

(Iron)

- Soft steel

- High tension steel

- Stainless steel

- Zinc plate steel

- Aluminum

MAG

MAG

General information

Select product

-

Low payload(3~8kg)

Manipulator specs

Manipulator specs

Manipulator specsLow payload(3~8kg)

- 1

- 2

-

Medium payload(15~25kg)

Manipulator specs

Manipulator specs

Manipulator specsMedium payload(15~25kg)

-

7-axis robot

Manipulator specs

Manipulator specs7-axis robot

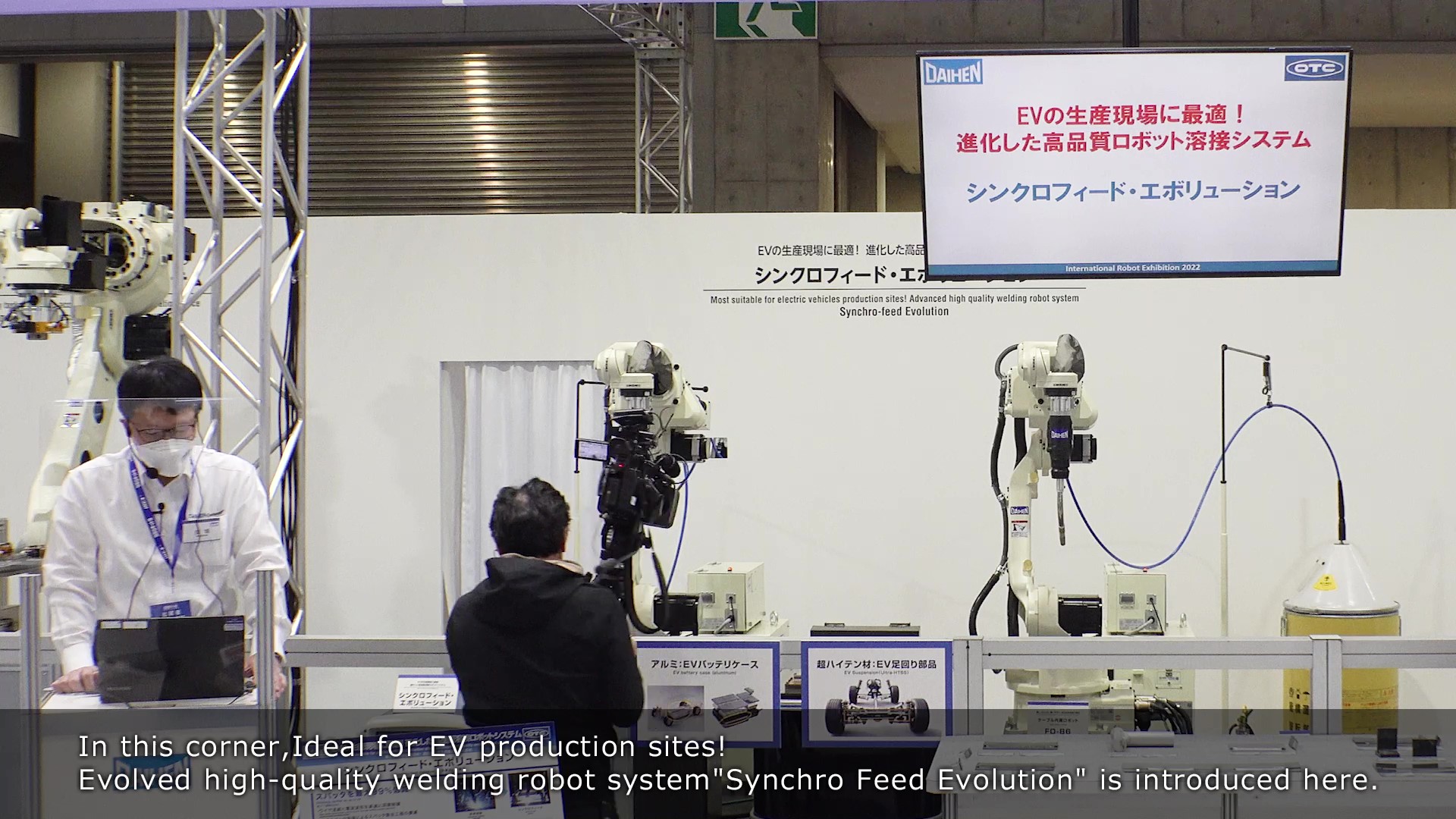

Video

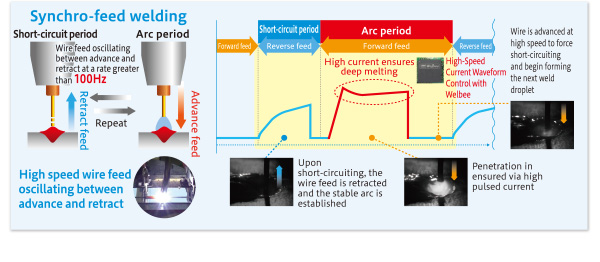

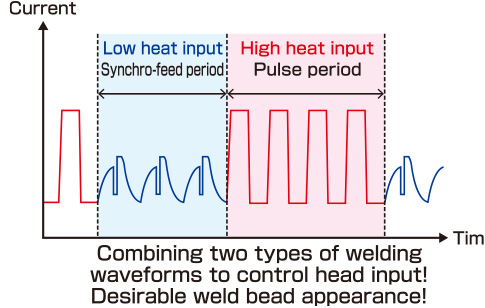

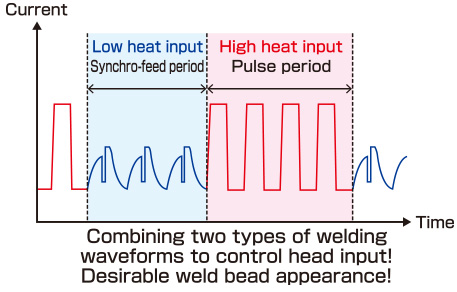

Synchro-feed Evolution